Palm Oil Extraction Plant

Description of the palm oil process

Located in Finca El Arenal, Municipality of Sayaxche, Petén, with an installed processing capacity of 60 tons/hr, the palm oil extraction process is energy-self-sufficient, burning excess biomass from the extraction process in a boiler designed for this purpose.

This process then generates energy in a steam turbine, estimated to produce 3000 kW/h, of which around 50% would be available for sale. The main processing equipment is developed and manufactured in Malaysia and Colombia.

Fruit Reception:

The bunches arriving at the processing plant are weighed and transported to the receiving hoppers. At this point, the quality assurance department conducts the respective evaluation of the fruit according to the company's criteria. After the evaluation, the fruit is unloaded into the hoppers and conveyed to the sterilization process using chain conveyors designed for this purpose.

Sterilization:

Sterilization is carried out in continuous sterilizers where the fruit is cooked with steam. The sterilization time depends on the ripeness of the fruit and can take from one hour to 1.5 hours. The steam used for cooking is at a maximum pressure of 3 bars (45 psi). This process has three main objectives:

- Softening the fruit bunches to facilitate separation in the next stage of the process.

- Inactivating the lipase enzyme, which breaks down the glycerol and carbon chains that make up fatty acids.

- Dehydrating the internal kernel of the fruit, causing it to detach from the surrounding husk.

Fruit Stripping:

As the sterilization process is continuous, conveyors transport the bunches to the fruit stripping process, where the fruits are separated from the bunches. This process is divided into two lines: one line carries all loose fruit to the digestion and pressing area, while the other, through chain conveyors, transports empty bunches to the empty bunch presses, which are then taken directly to the field for further use.

Digestion and Pressing:

The loose fruit from the fruit stripping process is macerated in digesters until a homogeneous soft mass is formed to extract the oil using a press. In this stage of the process, the fruits are pressed to extract a fluid containing a mixture of oil, water, and sludge. The remaining solid consists of kernels and fiber. The oily compound is pumped to the clarification and decantation process. The cake or solid part is defibrated to separate the kernels, which are sent to a drying process in a silo and then to the palm oil mill. The fiber is used as fuel for the boilers that generate steam needed by the plant. It is important that the temperature in this stage of the process and beyond should not be lower than 80°C.

Clarification:

The clarification process involves static and dynamic phase separation based on differences in densities. It can be done using static systems in vertical circular tanks with agitation, horizontal rectangular tanks, or dynamic systems such as centrifuges or decanters.

The clarified oil is then sent to a tank, where any remaining heavy materials or water are allowed to settle. This is done solely based on differences in densities and through resting. Subsequently, the oil is sent to the vacuum drying system. As this is a continuous process, the other phase, which consists of sludge with a low oil content, is centrifuged at around 1400 to 4500 rpm, ensuring that the effluent contains no more than 7000 ppm of oil at the end of the process.

Before sending this centrifuged sludge to the treatment system, it is sent to florentine tanks, which provide a residence time allowing for the separation of any remaining oil in the effluent.

Drying:

The drying process is done using vacuum dryers, which allow for the evaporation of any water present in the oil at low temperatures, ensuring optimal oil quality.

Storage of crude palm oil:

Once quality controls have been carried out in the laboratory, the oil is transferred to storage tanks to be dispatched to processing industries.

Fibrillation and Crushing:

The solid stream from the pressing process, which is a mixture of fiber and nuts, is dried to a required moisture content and then conveyed by screws for separation. The separation is a pneumatic process, where a vertical column is used through which an upward flow of air passes at a certain velocity so that all the fiber rises and the nuts fall to the bottom of the column because they are heavier.

The nuts are sent to the polishing drum to separate them from impurities and then to the drying and storage silo, where they are dried to facilitate the breaking of the shell and the recovery of the kernel contained within it. The collected fiber serves as fuel for the boilers and as natural fertilizer in the plantations.

Palm Oil Mill:

The dried nuts from the nut storage silos are sent to a drum equipped with screens, where they are classified by size before being sent to the nut crackers. After cracking, there is a mixture of shells and kernels, which are then separated into kernel and shell through a pneumatic separation process. It is worth noting that the final product is a kernel with a lower percentage of impurities (shell). The kernel is then passed to a drying silo.

An oil extraction system for palm kernel oil is installed, which consists of presses designed to extract the oil from the kernel until a cake with residual oil content close to 10% is obtained, and a palm kernel oil which is screened and filtered before being sent to the storage tanks.

The shell can be used as fuel in the boilers or for road maintenance within the plantations

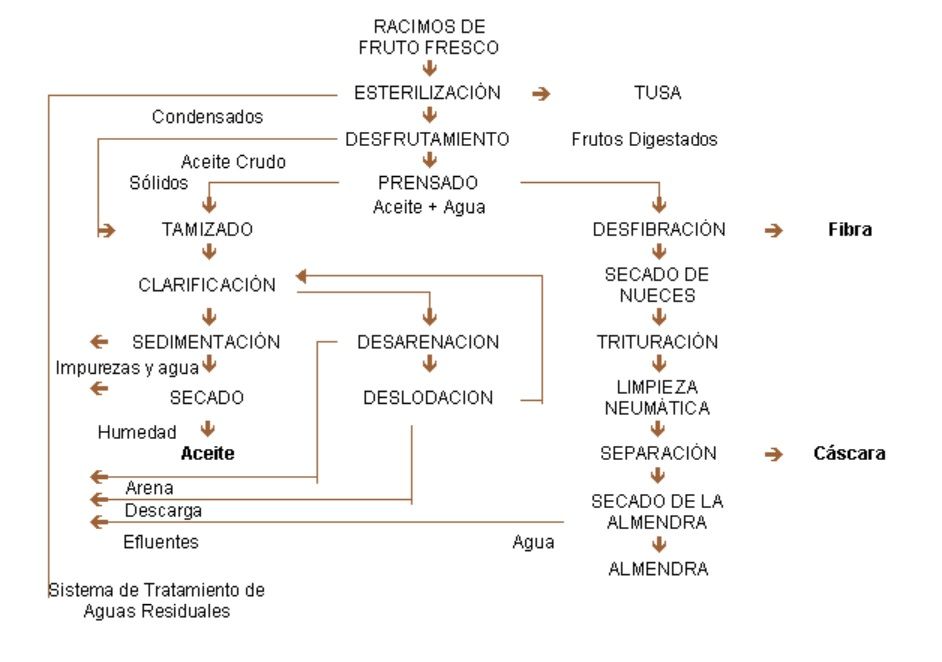

Flowcharts:

Here is the flow diagram of the palm oil extraction process, highlighting the main products and by-products.

Solid byproducts:

The solid byproducts generated by the extraction process are of great importance due to their composition, to be used in their entirety as organic fertilizers and primarily as fuels. The equivalent percentage portion, their characteristics, and values